A US factory that will produce batteries for hybrid and battery electric vehicles will receive an additional $2.5 billion investment from the Japanese automotive giant Toyota as per the company’s announcement on Wednesday, according to CNBC.

Considering the extra investment in Toyota Battery Manufacturing North Carolina, the firm is proud to announce that the total would now be $3.8 billion. Impressively, this amount is only a portion of a more extensive investment of up to $5.6 billion.

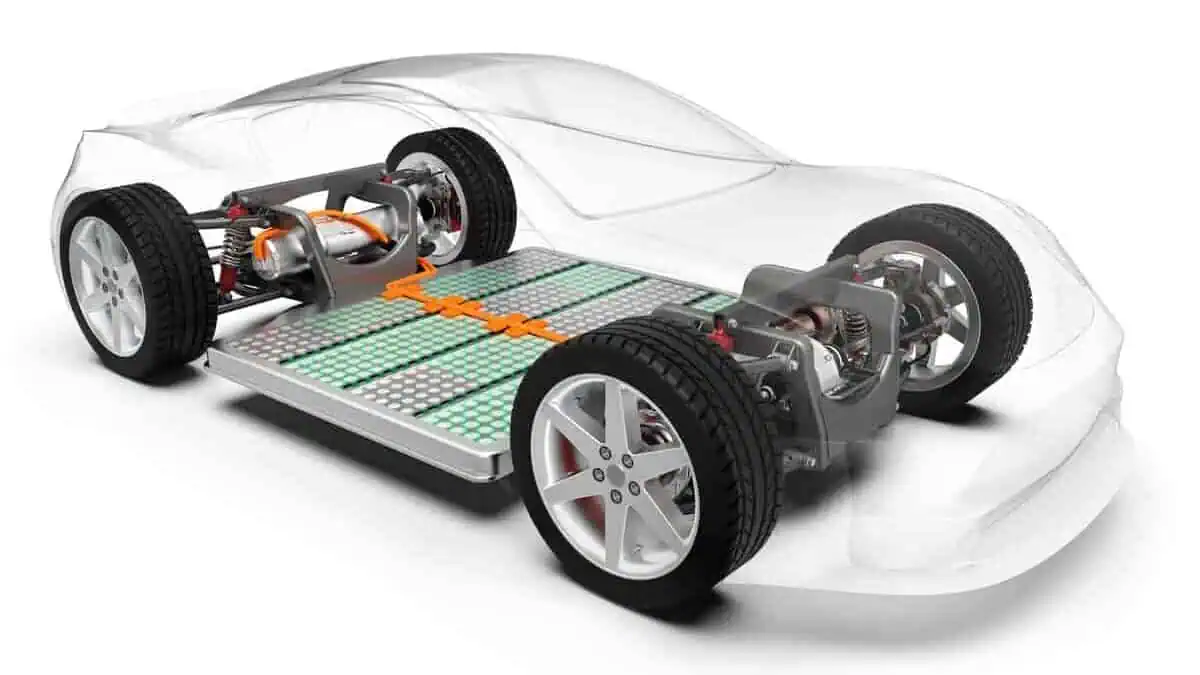

Indeed, Toyota takes the challenge of meeting EV battery demands seriously. Aside from its signature diesel, gasoline, hybrid, and fuel cell vehicles, it is now obviously seeking to catch up with leading firms in the battery-electric market, including Tesla and Volkswagen.

According to Toyota Motor North America’s senior vice president of unit manufacturing and engineering, Norm Bafunno, the announcement was “another big milestone” for the company.

The company stated that it would increase “combined battery production capacity” in the US and Japan by up to 40-gigawatt hours in order to achieve this.

Despite recent developments, it is still worth noting that over 2,000 of Toyota’s bZ4X all-electric SUVs were subject to a safety recall in June 2022.

Impressively, Toyota remains dedicated to not fully transitioning to electrics as it still considers many alternatives for the customers to choose from, even with its large investment in EV battery production.

According to Toyota’s statement regarding the new battery plant investment, the company is still seeking alternatives to battery powered EVs to help it fulfill stricter emission regulations.

“Toyota believes that there is more than one option for achieving carbon neutrality. It also believes that the means of reducing CO2 emissions as much as possible and as quickly as possible while protecting the livelihoods of its customers vary greatly depending on the country and region,” Toyota said in its statement. “With such in mind, Toyota will continue to make every effort to flexibly meet the needs of its various customers in all countries and regions by offering multiple powertrains and providing as many options as possible.”

In fact, Toyota Europe’s website shares the company’s insight, “internal combustion engine continues to be the most popular means of powering vehicles and it will continue to play a role for the next 20 to 30 years.”

On the contrary, recent rule approval by the California Air Resources Board mandates that by 2035, all new vehicles sold in the state must be zero-emission. On the other hand, the UK plans to stop selling new diesel and gas vehicles by 2030, and all new automobiles and vans must have zero tailpipe emissions starting in 2035. The same goals apply to the European Union to reduce carbon emissions.

The International Energy Agency estimates that 6.6 million electric vehicles will be sold worldwide in 2021. Sales of electric vehicles (EVs) reached 2 million in the first quarter of 2022, a 75% increase than the first three months of 2021.

All things considered, this investment in a battery plant may be Toyota’s strategy to qualify for the new federal tax credit as it requires that most of the battery components be extracted and built in North America.