Japanese manufacturer and distributor of electric motors, Nidec, will build a $715 million factory in Mexico, as per Nikkei Asia.

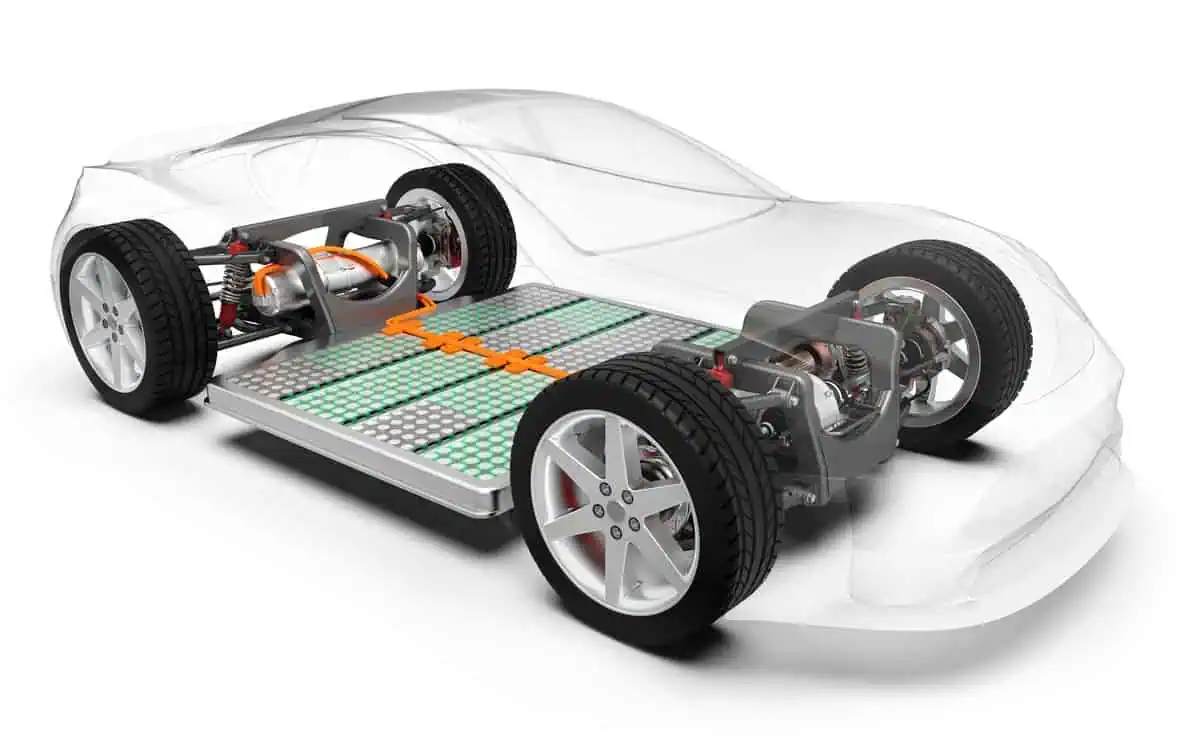

The plant will produce the “e-axle” drive system, combining an electric motor, power electronics, and transmission in a single unit.

According to Global Construction Review, the company currently makes the product in Germany and China. However, it plans to start production in America to meet an expected rush in the US market demand.

“As our basic operation, we produce products in a place and sell them locally,” said Nidec’s chairman and CEO, Shigenobu Nagamori. He emphasized that the company has maintained a local production for local consumption policy since its founding.

“We will spend some 300 billion yen in the coming three years. As we have received lots of inquiries, it would be too late to invest in new production after orders are placed.” said Nagamori in January.

Globally in 2020, the e-axle market was worth around $7.2 billion. However, it is predicted to expand to nearly $66 billion by 2028.

E-axle production by 2026

By 2026, the Kyoto-based company aims to make 5.7 million e-axles across seven locations (five of which will be in China and two in Europe), while the Mexican plant would be responsible for 1.3 million units.

Presently, it produces around 600,000 units annually, primarily for Chinese automotive companies Geely and Guangzhou Automobile Group (GAC).

No location for the Mexican plant was disclosed, but construction is anticipated to start during the 2023/24 financial year.

E-axle market

Competition for e-axle market share is increasing. For instance, Aisin has developed a family of second-gen e-axles and plans to release them for compact and other EVs by 2025.

Hitachi Astemo won an order to supply e-axles for Honda Motor EVs that the automaker plans to start global marketing in 2026.

Outside Japan, Magna International of Canada and Robert Bosch of Germany are also stepping up their e-axle businesses.