On Friday, General Motors disclosed plans to invest $760 million at its propulsion production facility in Toledo, Ohio. It is a part of the effort to prepare the factory for the manufacturing of drive units for upcoming Ultium-based battery-powered electric trucks, as reported by InsideEVs.

The primary goal of the project is to begin manufacturing drive units for the Ultium platform, particularly for the anticipated Chevrolet Silverado EV, GMC Sierra EV, and already available GMC Hummer EVs.

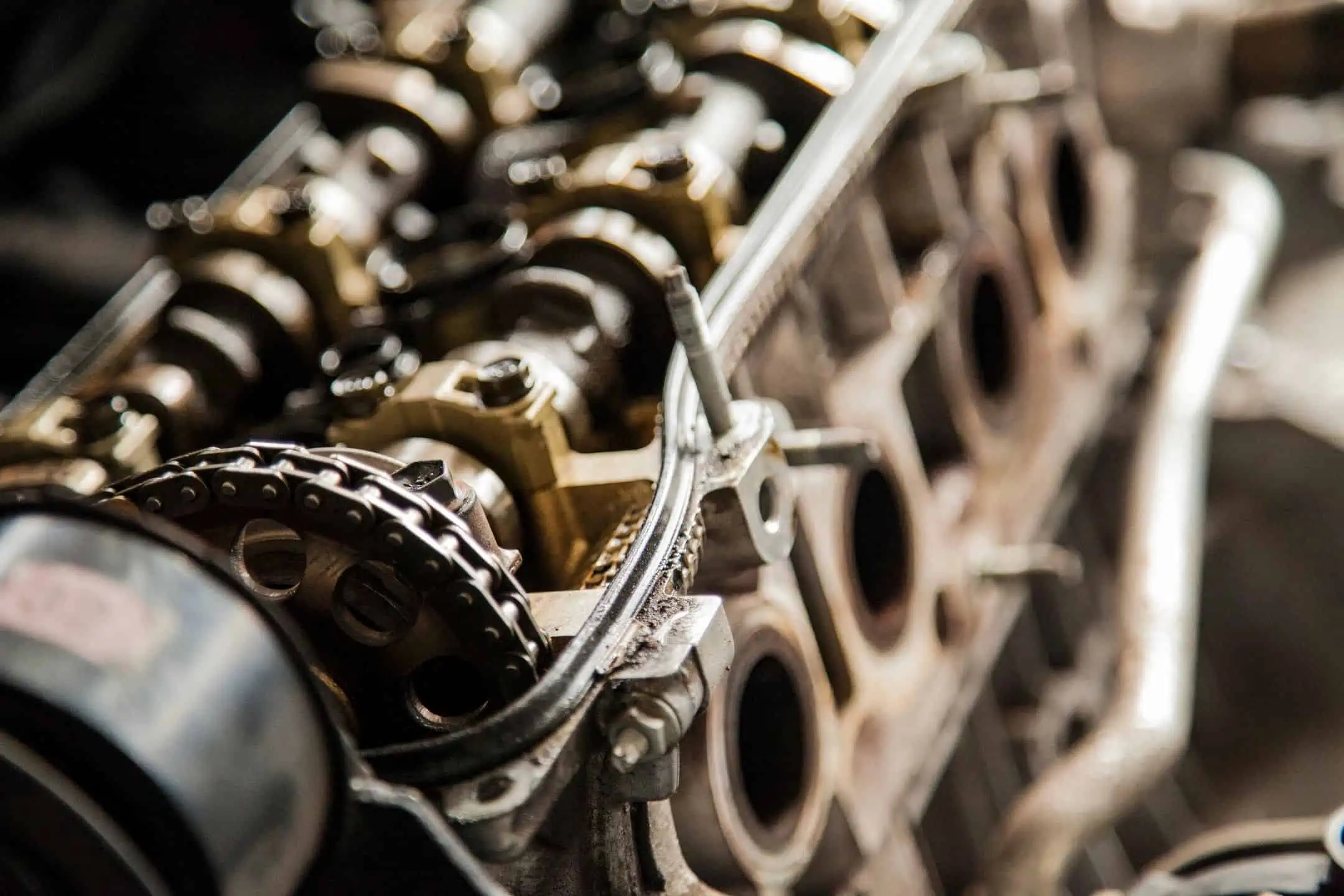

The Toledo Propulsion Systems now produces six-speed, eight-speed, and 10-speed rear-wheel drive gearboxes and nine-speed front-wheel-drive transmissions. It will be converted for electric vehicle production due to the additional investment, making it the company’s first US propulsion-related manufacturing plant.

Furthermore, this month will see the start of renovations at the facility, while transmission production will proceed as usual.

| “The Toledo Propulsion Systems team will continue building world-class transmission products while building drive units simultaneously during GM’s EV transition.” |

According to GM, Toledo Propulsion Systems will provide all variations of Ultium drive units, including high-performance and off-road capabilities. These variations include front-wheel drive, rear-wheel drive, and all-wheel drive propulsion combinations.

GM’s executive vice president for global manufacturing and sustainability, Gerald Johnson, stated:

| “Our Toledo team has a long, proud history of building great products and they have worked hard to earn this investment. This investment helps build job security for our Toledo team for years to come and is the next step on our journey to an all-electric future.” “Our Toledo team will continue to play a key role as we work to strengthen our current truck and SUV dominance, while also playing an important role in our EV growth transition,” |

One of several investments revealed in recent days is the one in Ohio. Additionally, GM is investing $491 million in its metal stamping operations in Marion, Indiana “to prepare the facility to produce a variety of steel and aluminum stamped parts for future products, including electric vehicles, built at multiple GM assembly plants”.

| “The investment will be used to purchase and install two new press lines, complete press and die upgrades, for renovations and to construct an approximately 6,000-square-foot addition. Work on the facility will begin later this year.” |

To boost the production of drive unit castings for the anticipated Chevrolet Silverado EV and other casting applications, the firm recently announced a $51 million expansion to its Bedford Casting Operations in Bedford, Indiana.

| “This investment is a recognition that UAW Local 14 members bring the skills, know-how and drive that make GM successful,” said UAW President Ray Curry. “UAW members look forward to being a part of shaping the future of General Motors.” |