A new axial-flux motor design from Texas-based Infinitum has undergone production with the promise of a modest 10% increase in operational efficiency, as per Motor Trend.

Why is this important?

The report stated that a planet-wide energy consumption of 25 petawatts (Pw) was predicted in 2020. Notably, electromagnetic devices, such as motors, were used to transport more than 40% of those electrons.

That said, gigawatts of energy could be saved by humanity with even minor increases in electric motor efficiency. Additionally, the ripple effects offer to rapidly increase the cost and energy savings.

The printed-circuit ‘Aircore’ motor

As per the publication, the Infinitum Aircore electric motor’s stator differs from the industry-standard iron or steel armature wrapped in round or square copper wire.

Interestingly, a round, flat epoxy-glass circuit board with complex copper wires engraved on it serves as the stator in this system.

Meanwhile, the rotors essentially follow the convention for pancake-style axial-flux motors. Depending on the application and available funds, a steel disc with magnets attached to it may or may not be rare-earth.

Notably, this design is 50% smaller and lighter and utilizes 66% less copper for any assigned power rating. Moreover, 43 pending and 33 granted patents cover its intellectual property.

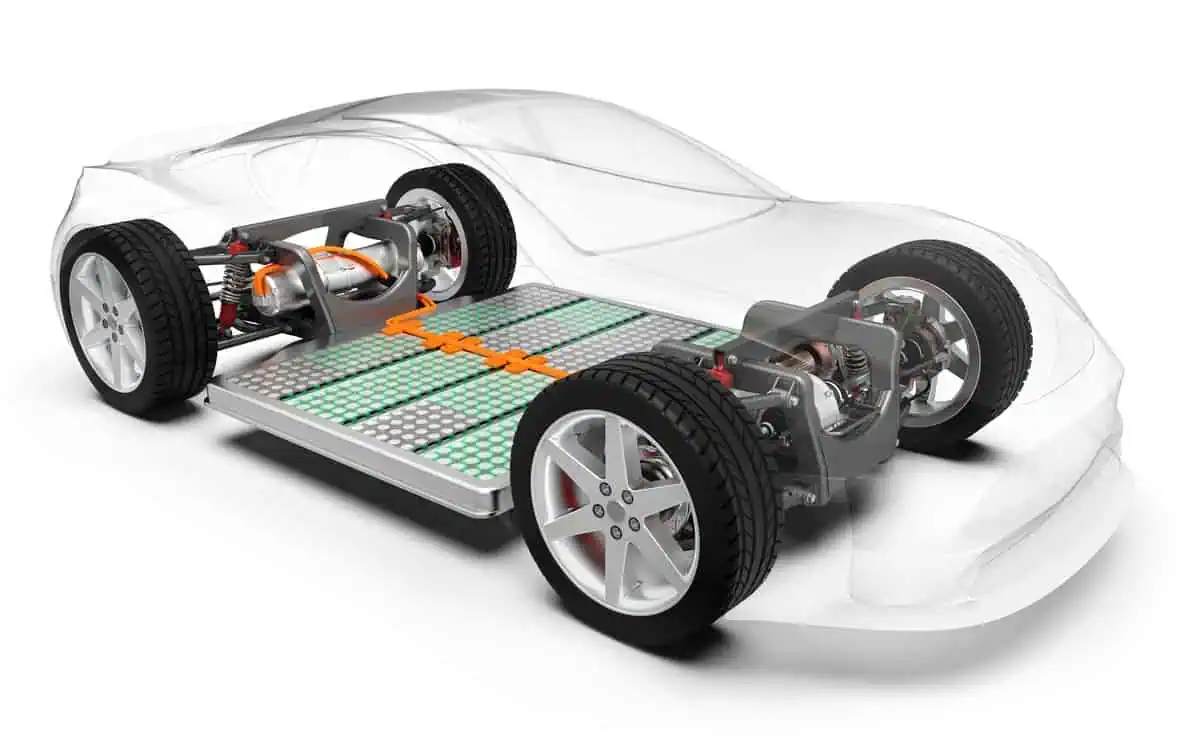

In 2023, a new factory in Mexico will produce 50,000 small industrial motors, with an increase in production the following year. The firm announced its first traction motor application designed for EVs at CES 2023.

Improved cooling

Interestingly, the term “Aircore” refers to the absence of iron in the electromagnetic flux path in place of mere air. In the case of the traction motor, this implies cooling oil or air can reach the heat source directly.

This design is significantly superior to cooling a stator alone with its housing or copper end windings. Compared to a motor with conventional copper windings, an Aircore motor can handle four to five times the current density.

That capability significantly raises the power density of the Aircore motor. Furthermore, the gain in operating efficiency can be largely attributed to the decreased heat losses.

Inside the traction motor

As per the publication, the first motor displayed at CES has four permanent-magnet disc rotors between three printed-circuit stators. It is said to be wound for a three-phase process.

“Cooling oil enters under pressure through the output shaft, flowing axially out to directly cool the copper traces before collecting in a sump at the bottom.”

Motor Trends

Remarkably, it is capable of 201 continuous and 402 peak horsepower. It may be possible to maintain peak power longer with this design than with others because of its superior cooling capability.

Knock-On Savings

Having lighter and more efficient motors is expected to increase the traction motor’s efficiency, extending the range and/or shrinking battery size by more than that 10%.

Additionally, Infinitum motors are completely serviceable, lowering the total ownership cost.

Moreover, all parts are easily recyclable once the replacement of bearings, stators, and rotors has substantially extended their useful service life.

For comparison, a significant number of motors using our petawatts end up in landfills once they fail to function.

Apart from that, two times the number of industrial equivalents can fit in a shipping container since smaller, lighter motors are less expensive and more environmentally friendly to ship.

Untapped potential

Remarkably, the switchable variable-phase windings used in printed-circuit stators are naturally suited to changing from three-phase to 12 or even 18 distinct electromagnetic phases.

As seen by the Chorus Meshcon motor that will soon be used in WheelTug aircraft nose gear, it modifies the torque/speed characteristics and creates a “virtual transmission.”

Furthermore, the publication noted that Infinitum motors might be more appealing for in-wheel motor uses with lighter stators because they can aid in reducing unsprung mass. Through this, the ride qualities of Indigo’s Robotic Wheel active-suspension may be significantly enhanced by these lighter axial-flux motors.

Coming soon

As per the report, Formula E evaluates the said technology, while Infinitum already has deals with major international trucking and construction equipment companies. Beginning in Q3 2023, the first traction motors will leave the manufacturing lines.

However, we can only hope this technology can aid in lowering the EVs’ demand for electrons, which will assist in partially squelching the 25 pW worldwide electricity need.