| Rank | Innovation | Description | Key Benefits |

| 1 | Multiphase flow cooling plates | Utilize different phases of coolant (liquid, vapour) for targeted heat transfer within the battery pack. | Improved cooling efficiency, and reduced energy consumption. |

| 2 | Direct cooling of battery modules | Coolant flows directly around individual battery modules instead of the entire pack, enabling precise temperature control. | More efficient heat removal, reduced weight and complexity. |

| 3 | Phase change materials (PCMs) | Integrate PCMs into the battery pack to absorb and release heat passively, regulating temperature fluctuations. | Improved safety, extended battery lifespan, and reduced cooling system size. |

| 4 | Microchannel heat sinks | Employ intricate networks of tiny channels for efficient heat transfer, maximizing surface area within limited space. | Lightweight, compact design, enhanced cooling performance. |

| 5 | Two-phase loop cooling | Leverage phase change of coolant to transport heat away from battery pack efficiently, requiring less pump energy. | High heat removal capacity, lower energy consumption. |

| 6 | Dielectric coolants | Utilize electrically insulating liquids that can be directly in contact with battery cells for enhanced cooling. | Improved cooling efficiency, and simplifies system design. |

| 7 | Machine learning (ML)-based thermal management | Utilize ML algorithms to predict and optimize battery temperatures in real time, adapting to driving conditions. | Proactive and efficient cooling, extended battery life. |

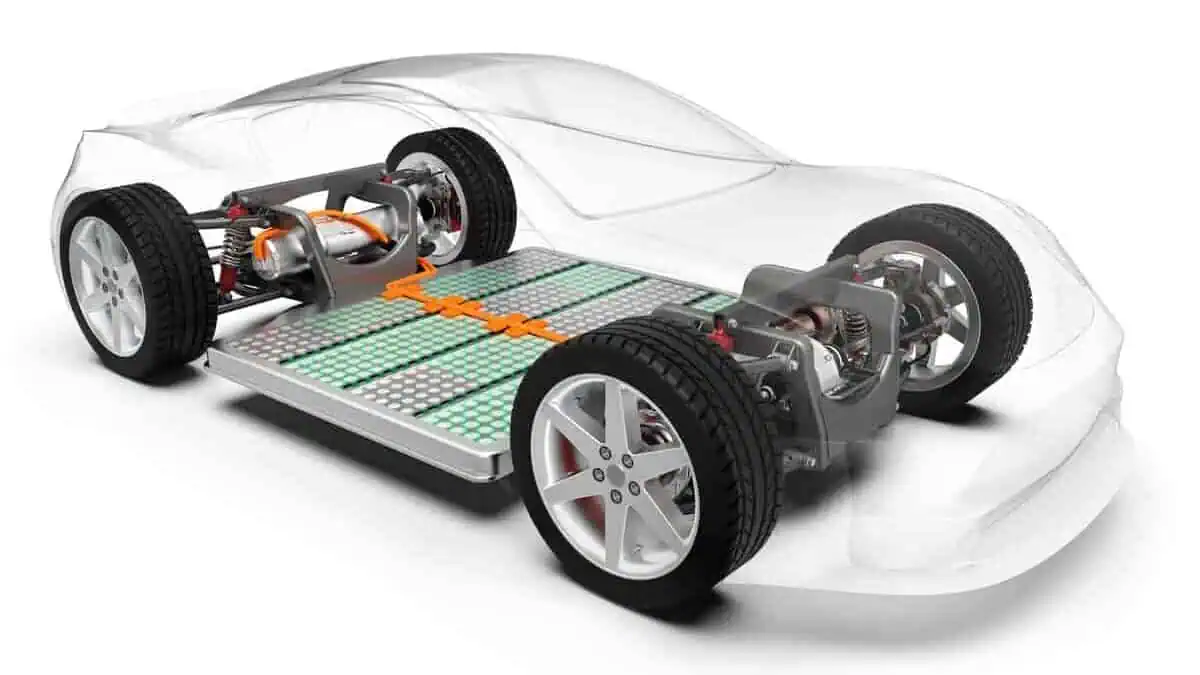

| 8 | Integrated battery and cooling system architectures | Combine battery modules and cooling components into a single unit, simplifying design and improving heat transfer. | Reduced weight, and complexity, and improved packaging efficiency. |

| 9 | Nanocomposite coolants | Enhance the thermal conductivity of coolants using nanoparticles for better heat transfer within the system. | Improved cooling performance, and potentially reduced coolant flow required. |

| 10 | Conformal cooling technologies | Apply flexible, form-fitting cooling elements directly onto battery modules for precise and efficient heat extraction. | Lightweight, adaptable design, maximizes heat transfer surface area. |

| 11 | Waste heat recovery systems | Capture waste heat from the battery pack and utilize it for cabin heating or powering auxiliary systems. | Improved energy efficiency, and reduced reliance on additional heating sources. |

| 12 | Battery-in-chassis cooling | Integrate cooling channels into the vehicle chassis itself, leveraging its larger surface area for heat dissipation. | Reduced need for additional cooling components, potentially lighter weight. |

| 13 | Smart air ventilation systems | Utilize intelligent control of airflow through the battery pack for targeted cooling based on real-time needs. | Optimized cooling performance, minimizes energy consumption from fans. |

| 14 | Bio-inspired cooling systems | Draw inspiration from nature’s heat transfer mechanisms, such as mimicking animal sweat glands or plant vascular systems. | Sustainable, potentially lightweight and efficient cooling solutions. |

| 15 | 3D-printed cooling channels | Utilize additive manufacturing to create complex, customized cooling channels within the battery pack for optimal heat transfer. | Lightweight, flexible design, freedom for optimizing coolant flow paths. |

| 16 | Self-healing coolants | Develop coolants with the ability to automatically repair minor leaks or damage, improving system reliability and safety. | Reduced maintenance needs, and enhanced system robustness. |

| 17 | Solid-state electrolytes | Employ solid-state electrolytes in batteries, enabling higher operating temperatures and simplified cooling systems. | Potentially improved safety, and higher energy density, but still under development. |

| 18 | AI-powered predictive maintenance | Leverage AI to predict potential cooling system failures and recommend preventive maintenance, reducing downtime and costs. | Improved system reliability, and optimized maintenance schedules. |

| 19 | Cloud-based thermal management platforms | Implement cloud-based data collection and analysis to monitor and optimize battery thermal performance remotely. | Real-time insights, centralized data management, and improved fleet management. |

| 20 | Open-source collaboration | Promote open-source development and sharing of knowledge related to EV battery cooling technologies to accelerate innovation. | Faster development cycles, and wider access to promising solutions. |