In an effort to significantly increase the manufacture of electric vehicles in North America amid supply constraints and escalating prices, General Motors has partnered with a Canadian battery recycler, Lithion Recycling. TechCrunch reported that this investment aims to create new batteries from recovered battery materials.

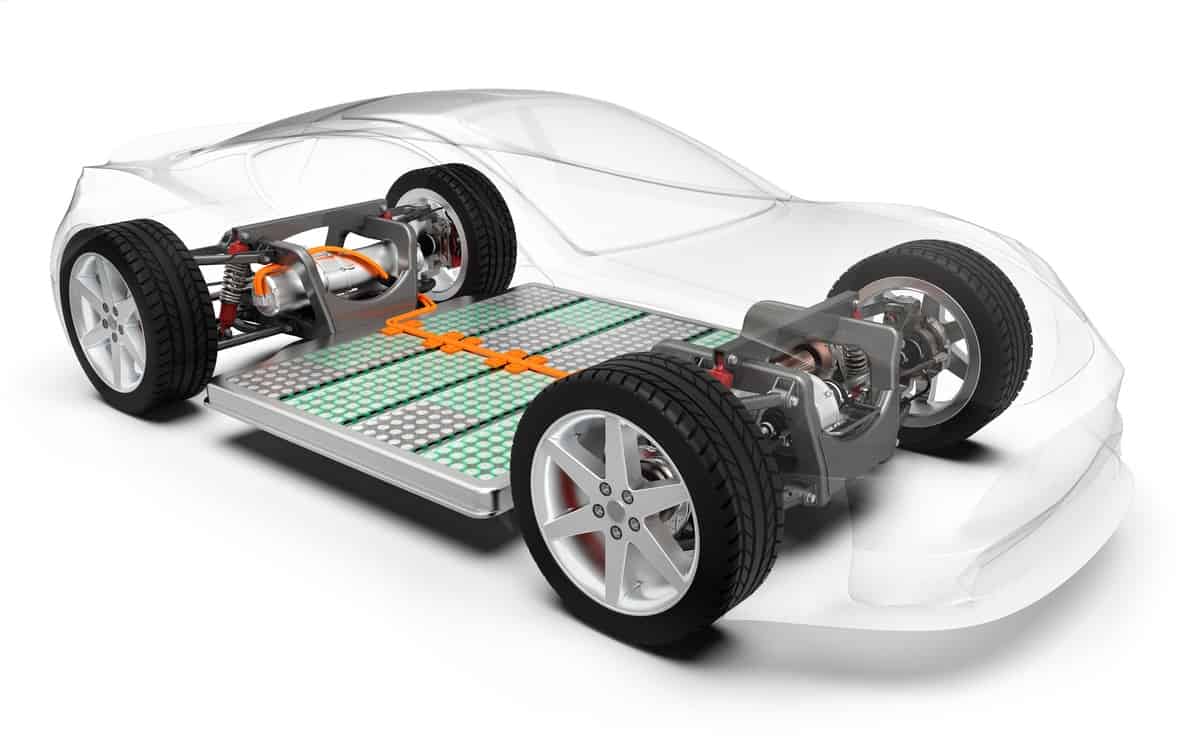

Lithion Recycling obtained funding in a Series A round from the automaker through its GM Ventures division. As the industry pushes to shift away from gasoline engines by the decade’s end, the partnership will strive to develop a circular ecosystem for recycling EV batteries.

It is worth noting that developing enough charging stations to serve the large number of battery-electric vehicles anticipated to be present by 2030 has been the primary emphasis of the global EV deployment up until recently.

However, the COVID-19 and the Ukraine conflict disrupted global supply chains and increased the cost and scarcity of the raw materials required to make batteries. By outsourcing job operations and integrating more of the battery lifecycle in-house, GM and other manufacturers attempt to exert more control over the supply.

AquaMetals estimates that by 2030, when most manufacturers aim to phase out gas-engine vehicles, almost 15 million tons of lithium-ion batteries will have reached their end of life.

Remarkably, GM-Lithion partnership is expected to aid the automaker develop:

| “a supply chain and recycling strategy that can grow with us,” Jeff Morrison, GM’s vice president of global purchasing and supply chain, stated. “In Lithion’s technology, we see the opportunity to recover and reuse raw material in our Ultium battery packs, making the EVs we produce even more sustainable and helping drive down costs,” Morrison said. |

With a capacity of 7,500 metric tons of lithium-ion batteries annually, Lithion intends to commence its first commercial operations in 2023. In 2025, Lithion plans to open its first hydrometallurgical facility.